We are always looking for ways to improve and expand our capabilities as a custom part manufacturer. We are excited to announce that we are now offering 3D printing in both steel and carbon-fiber. Additive manufacturing is the future, helping us reduce waste and drastically reduce lead times.

The MarkForged 3D printer allows us to make plastic, carbon fiber, and nylon parts. Our new 3D Systems ProX DMP 300 gives us the ability to produce solid metal pieces in a faster, more cost-effective way. We can print in maraging steel (like 4140 or tool steel) For example, we were able to print this beautifully detailed helical gear for a customer overnight, remove the support material and have it inspected the next day and then shipped out. We’ve never been able to provide service this fast before. The addition of 3D printing technology to our already state-of-the-art operation keeps Metalmite on the cutting edge of the industry.

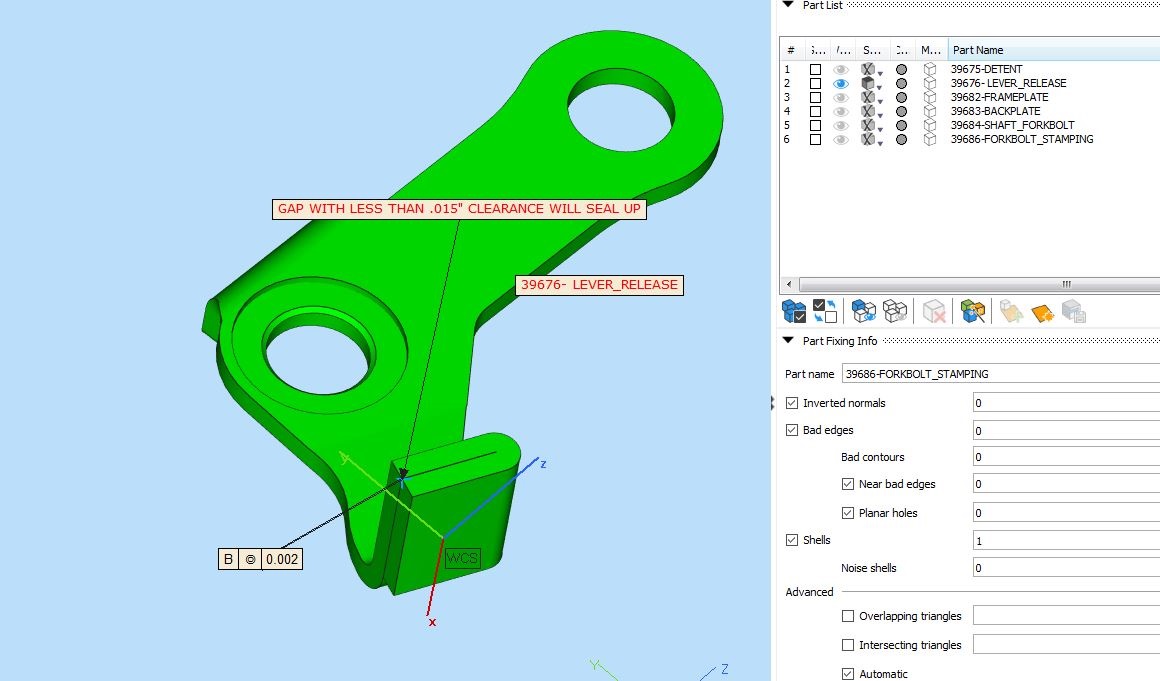

As one of the largest 3D metal printers on the market, we can print large parts in the 10x10x13 inch working envelope. Parts that cannot typically be made with traditional, subtractive manufacturing techniques can now be designed for additive manufacturing  and printed in a couple of days. Mold bases with integrated water lines and parts with specific internal cooling lines can now be printed in hours. The best results come

and printed in a couple of days. Mold bases with integrated water lines and parts with specific internal cooling lines can now be printed in hours. The best results come

when Metalmite works side-by-side with the design engineers to maximize the

effectiveness of the design for additive manufacturing.

If you’re looking to take a concept from your head and put a part in your hand – Get it Machined or 3D Printed. Get in touch with us today!