Cutting Gears and Splines in Rochester

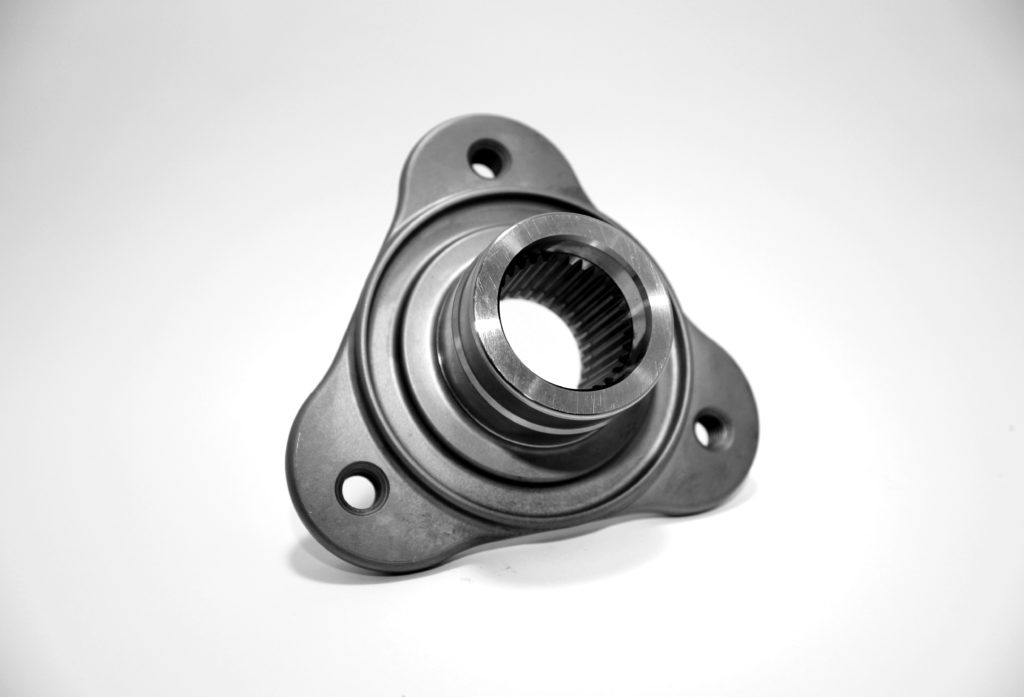

Metalmite has been making gears and splines for decades. The roots of our family business are with Michael Gendich II (MGII) in Downtown Detroit in the 1940’s. MGII was the first person to bring a Herringbone Gear Cutter into Michigan for large gears. We have been told that this gear cutter is still being used today in the Detroit area! With primary clients in that day being Massey-Ferguson Tractor, Chevrolet Gear and Axle, and others; gear cutting was a primary service to offer. Today Metalmite uses multiple methods to cut gear teeth and splines. Metalmite’s Wire EDMs are accurate enough to cut the gages used by most gear cutters. We also use Live tooling hobbers to cut splines while in the turning operations. We can shaper cut or mill teeth on as well. And we have a large supply of gear cutting shops capable of cutting, broaching, and grinding any kind of tooth profile! We look forward to helping you with your next project!

The Facts

- Gear Cutting: We can offer the following types of gears- Spiral bevel, spur, miter, straight bevel, helical, worm gears and more!

- We can cut gears using Hob Machines, Shaper cutters, live tooling, or milling hobs

- We can get splines rolled using several of our certified spline roll suppliers

- We can also gear grind using several of our certified Gear Grinding sources