Proven and Trusted in CNC Machining and 3D Printing Excellence

Since 1968

Metalmite is capable of much more than manufacturing. Our team offers 3-dimensional cad-cam services, capable of transforming even the simplest sketch into a precision component. Whether it is reverse engineering or making it to a customer design, MetalMite has the experience and capability to handle your next project. And at the end of the process our clients appreciate free pick-up and drop-off in the greater Detroit area, as well as hassle-free national and international shipping for those abroad.

While our quality speaks for itself, it’s the simplicity of the Metalmite process — from development to delivery — that makes MetalMite stand out from the competition. Metalmite truly is a unique machine shop — from the quality of our workmanship to the quality of our people.

Request a Quote today from [email protected]

High-Speed Milling

Faster machining, better finishes and less expensive, high-quality parts. Metalmite is capable of speeds up to 45,000 RPM.

5-Axis Milling

Machining on our Mori Seiki NMV 5000 DCG helps reduce, and in some cases even eliminate, most NON-Value added processes.

6-Axis Turning & Milling

Like two CNC lathes back-to-back with a full CNC Machining center mounted on top; all working together to make your parts faster, better, and cheaper.

Wire EDM

Multi-heads, controls for preventing wire breakage, automatic self-threading, and machining strategies to optimize the operation.

Conventional Machining

With manufacturers such as Bridgeport, H.E.S., Sheldon, Southwestern Industries/ProtoTrak, we have the ability to process any job.

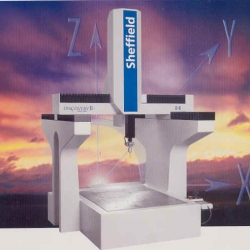

Inspection

Metalmite adheres to the International Organization of Standardization (ISO) code 9001:2015 for their quality procedures.

Additive 3-D Printing

We have added a couple 3D printers that are allowing us to offer solutions in hours instead of days or weeks.

Gear Cutting

Gear Cutting: We can offer the following types of gears- Spiral bevel, spur, miter, straight bevel, helical, worm gears and more!

CNC Grinding

Metalmite has several Inner and Outer Diameter grinders in house. They have a maximum work area of 10” diameter by 40” between centers.

Metalmite Specializes in:

- Turning

- Milling

- Grinding- ID, OD, Flat

- Wire EDM

- Welding

- Sheet Metal Bending

- Spline Rolling

- Shaper Cutting

- Hobbing

- Gear Grinding

- Thread Rolling

- Thread Grinding

- Plating

- Painting

- Coating

- Etching

Our quality and versatility has given us the opportunity to work with diverse companies from a variety of industries:

Automotive

Aerospace

Defense

Commercial

Medical

Plastics

Equipment

C.N.C. MILLING EQUIPMENT (12 Machines)

(2) Mori Seiki NMV5000DCG 5-Axis machining center (28”x20”x20”) and turning (27.5”dia x 17.7”)

(1) OKK VM7 4-axis machining center (60” x 30” x 26” ) with C.N.C. rotary table.

(1) Mori Seiki SV500B/50 4-axis machining center (40” x 20” X 20”) with C.N.C. rotary table.

(1) Mori Seiki 5000/40: 4-axis machining center (30” x 20” x 20”) with C.N.C rotary table.

(1) Mori Seiki SV500/40: 3-axis machining center (30” x 20” x 20”) with 40,000RPM attachment

(1) Mori Seiki NV1500DCG: 3-axis machining center (6” x 6” x 8”) with 24,000RPM spindle

(1) TRAK FHM5 Mill: 3-axis machining center (34” x 10” x24”) with C.N.C. SMX control.

(1) TRAK DPM Mill: 3-axis machining center (34” x 10” x24”) with C.N.C. A.G.E. 3 control.

(3) Bridgeport milling machines w/ Prototrak MX2 2-axis C.N.C. control.

C.N.C. MULTI-TOOL MACHINE EQUIPMENT (4 Machines)

(1) Mori Seiki NL-2500SY: C.N.C. lathe (14” dia. x 27” b/w centers) 5 Axis Dual Spindle w/Live Tooling

(1) Mori Seiki NL-2000SY: C.N.C. lathe (14” dia. x 20” b/w centers) 5 Axis Dual Spindle w/Live Tooling

(1) Miyano BND-51S2 C.N.C. lathe (6” dia. x 12.6” b/w centers) 4 Axis Dual spindle w/Live Tooling

(1) Samsung SL35BMC C.N.C. lathe (20” dia. x 60” b/w centers) 4 Axis Single spindle w/Live Tooling

C.N.C. TURNING EQUIPMENT (6 Machines)

(1) Mori Seiki TL-40B: C.N.C. lathe (20” dia. x 120” b/w centers) with hydr. steady rest.

(1) Samsung SL-25: C.N.C. lathe (13.8” dia. x 44” b/w centers) with hydr. steady rest.

(2) Mori Seiki SL-25A: C.N.C. lathe (13.8” dia. x 44” b/w centers) with hydr. steady rest.

(1) Mori Seiki CL-25B: C.N.C. lathe (13.8” dia. x 17” b/w centers) with collet attach.& bar feeder.

(1) TRAK TRL 1840: C.N.C. lathe (18” dia. X 40.2” b/w centers)

C.N.C. Grinding (1 Machine)

(1) Toyoda Select G100II C.N.C. (12 x 40) (New 2012)

C.N.C. WIRE EDM (2 Machines)

(1) AgieCharmilles Cut 200 P Wire EDM (8.6×8.6×13.8) 5 Axis submersible (New 2014)

(1) Charmilles Robofil 440SL Wire EDM (21.6×13.7×15.75) 5 Axis submersible (New 2005)

CONVENTIONAL TURNING EQUIPMENT (2 Machines)

(1) H.E.S. Tracer Lathe (20” dia. x 72” b/w centers) with traveldials & steady rest

(1) Sheldon Precision Tool Room Lathe: 13” dia. x 32” b/w centers) with collet attachment

CAD/CAM EQUIPMENT

(1) DELL PC: with Gibbs CAM 2D machining software

(2) DELL PC: with Gibbs CAM 3D solid machining software and AutoCAD/LT Note: Please e-mail cad files in .IGS,.X_T,.XMT,.PAR,.SLDPRT,.DXF, or .DWG formats

SURFACE GRINDING EQUIPMENT (3 Machines)

(1) Okamoto Surface Grinder: with 16” x 32” x 18” magnetic chuck

(2) Reid Surface Grinders: with 6” x 18” magnetic chuck and diamond grinding wheels

I.D. & O.D. GRINDING EQUIPMENT (4 Machines)

(1) Jones & Shipman Model 1300X universal grinder: (10” x 30”) with Microprocessor control

(1) Jones & Shipman Model 1300 I.D./O.D. universal grinder: (10” x 30”) with Sony digital

(1) Toyoda I.D./O.D. universal grinder (10” x 40”) with Sony digital

(1) Jones & Shipman Model 1600 Center Lap

JIG GRINDING EQUIPMENT (1 Machine)

(1) Moore #3 Jig Grinder (12” x 24”) with Sony digital readouts

INSPECTION EQUIPMENT

(1) Sheffield CMM Discovery II (2003)

GENERAL SHOP EQUIPMENT

(6) Assorted drill presses.

(1) Sunnen Hone model MBB – 1650.

(1) Powermatic hydraulic table saw 18”.

(1) Behringer HBP 220 Automatic horizontal saw.