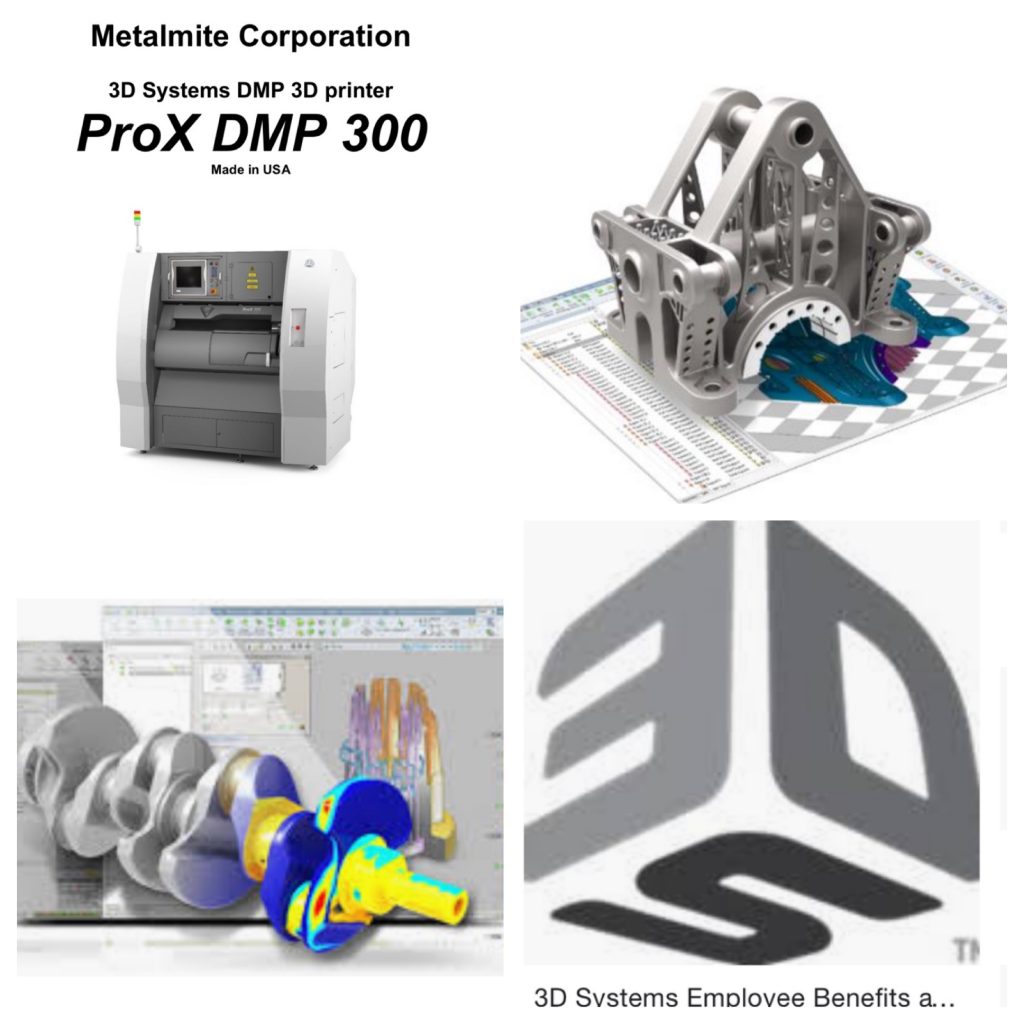

As we have started using the 3D printers now at Metalmite we are finding new uses everyday! We have used the Carbon-fiber and the Nylon in several applications and have learned that there are even more uses than we imagined. The 17-4 printer is close to ready and we look forward to printing the steel parts very soon! Metalmite will be capable of printing aluminum, tool steel, stainless, and HSLA now.

According to an article in 3dprintingindustry.com “The proposed U.S. military budget for 2018 includes support for an increased use of 3D printing and additive manufacturing. Every year Washington must authorize appropriations for the coming fiscal term. The funds pay for military activities of the Department of Defense, military construction, personnel and for other purposes. The total budget to be approved for 2018 is $639.1 billion. Among the planned expenditure on aircraft carriers and the need to appoint a chief technology officer, details related to additive manufacturing are given.”

“Metalmite has long been a leader in innovative solutions using 5-6 axis and Wire EDM to machine precise details for the aerospace and military industry. Now with the addition of 3D printing we can offer faster leadtimes and reduced cost to this process.” Says Tom Gendich, President of Metalmite Corporation.

“Metalmite has long been a leader in innovative solutions using 5-6 axis and Wire EDM to machine precise details for the aerospace and military industry. Now with the addition of 3D printing we can offer faster leadtimes and reduced cost to this process.” Says Tom Gendich, President of Metalmite Corporation.

Ask for a quote today by clicking this email.

Ford has been using 3D printing for many years. Many OEM’s are now incorporating this into their strategy.

“Believe it or not, Ford has been using 3D printing to an extent since back in the 1980s. Call the automaker an early adopter, because back then most people had no idea such a thing existed. In fact, in 2017 the company exceeded 500,000 vehicle parts made using a 3D printer.

As the first automaker to try out the Stratasys Infinite Build 3D printer, Ford could be taking a big and bold step toward integrating 3D printing into its manufacturing processes.” as found here.