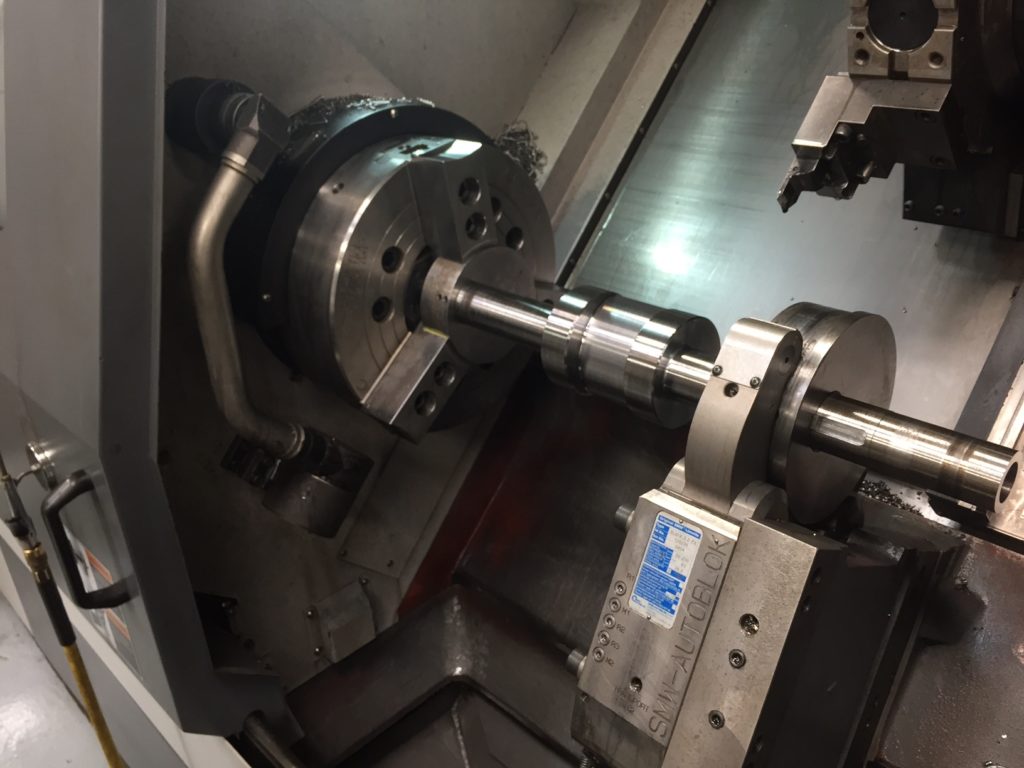

Making a crankshaft is a difficult process that many shops cannot do successfully. A few years ago a customer asked Metalmite to get involved a manufacture a crankshaft that the original company could no longer make. We went to work and developed a process that uses eccentric fixtures and multiple centers to be able to turn and grind these crankshafts. Using our 6 axis CNC turning centers we can do more of the operations than we originally could with only a 2 axis lathe. We can offer live tooling and surfacing on the parts as well today.

At Metalmite Corporation, a CNC machine shop located in Rochester, Michigan, just outside of Detroit, we use Mori Seiki CNC Lathes with main spindle, programmable sub-spindle, live-tooling and axes. They are the ultimate in Multi-Tasking lathes. Talk about LEAN machine cells, these machines are like two CNC Lathes back-to-back with a full CNC Machining center mounted on top; all working together towards a common goal, your parts faster, better and cheaper. Raw material goes in and finished parts come out. This virtually eliminates all Non-Value-Added activity in the machining process. No need for multiple fixtures and fixturing, no wait time going from machine to machine, no Batch and Queuing just pure LEAN processing. See more here