Wire EDM Cutting for Precision Parts

Metalmite, located in Rochester, Michigan — approximately 20 miles outside of Detroit — has invested in the best Wire EDM equipment available to benefit their customers. People often ask “What is Wire EDM?” and “How does it cut metal so accurately and precise?” Well, here is how it works; in wire electrical discharge machining (WEDM), or wire-cut EDM, a thin single-strand metal wire, usually brass, is fed through the workpiece, typically occurring submerged in a tank of dielectric fluid.

Metalmite, located in Rochester, Michigan — approximately 20 miles outside of Detroit — has invested in the best Wire EDM equipment available to benefit their customers. People often ask “What is Wire EDM?” and “How does it cut metal so accurately and precise?” Well, here is how it works; in wire electrical discharge machining (WEDM), or wire-cut EDM, a thin single-strand metal wire, usually brass, is fed through the workpiece, typically occurring submerged in a tank of dielectric fluid.

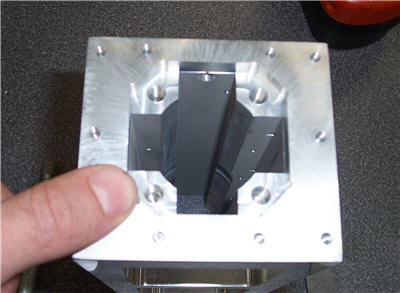

This process is used to cut plates as thick as 300mm and to make punches, tools,and dies from hard metals that are too difficult to machine with other methods. The wire, which is constantly fed from a spool, is held between upper and lower diamond guides. The guides move in the x–y plane, usually being CNC controlled and on almost all modern machines the upper guide can also move independently in the z–u–v axis, giving rise to the ability to cut tapered and transitioning shapes (circle on the bottom square at the top for example) and can control axis movements in x–y–u–v–i–j–k–l–. This gives the wire-cut EDM the ability to be programmed to cut very intricate and delicate shapes.

The wire is controlled by upper and lower diamond guides that are usually accurate to 0.004 mm, and can have a cutting path or kerf as small as 0.12 mm using Ø 0.1 mm wire, though the average cutting kerf that achieves the best economic cost and machining time is 0.335 mm using Ø 0.25 brass wire. The reason that the cutting width is greater than the width of the wire is because sparking also occurs from the sides of the wire to the work piece, causing erosion. This “overcut” is necessary, predictable, and easily compensated for.

Spools of wire are typically very long. For example, an 8 kg spool of 0.25 mm wire is just over 19 kilometers long. Today, the smallest wire diameter is 20 micrometres and the geometry precision is not far from +/- 1 micrometre. The wire-cut process uses water as its dielectric with the water’s resistivity and other electrical properties carefully controlled by filters and de-ionizer units. The water also serves the very critical purpose of flushing the cut debris away from the cutting zone. Flushing is an important determining factor in the maximum feed rate available in a given material thickness, and poor flushing situations necessitate the reduction of the feed rate.

Along with tighter tolerances multiaxis EDM wire-cutting machining center have many added features such as: Multiheads for cutting two parts at the same time, controls for preventing wire breakage, automatic self-threading features in case of wire breakage, and programmable machining strategies to optimize the operation.

Wire-cutting EDM is commonly used when low residual stresses are desired. Wire EDM has no added residual stress because it has no cutting forces. There is little change in the mechanical properties of a material in wire-cutting EDM due to these low residual stresses.

SIGN UP FOR UPDATES!

Get news from Metalmite Corp. in your inbox.