Additive 3-D Printing

3D From Nothing

By Thomas Gendich

Listen now

![]() Pocket Casts |

Pocket Casts | ![]() Spotify |

Spotify | ![]() RSS |

RSS | ![]() iTunes

iTunes

3D PRINTING ISN’T JUST FOR PLASTIC PARTS ANYMORE

When you work in a high-stakes industry like military defense, aerospace, or space, you’re probably accustomed to using CNC machining or injection molding to produce your parts.

But these traditional manufacturing methods can be slow and expensive—not to mention limiting when it comes to factors like design complexity and customization. If you’re used to working with metal, it’s easy to overlook a third manufacturing option: 3D printing.

Want to learn more about what 3D metal printing has to offer?

Tom Gendich

President of Metalmite Corporation

Would you like to join us on the podcast?

Contact us today:

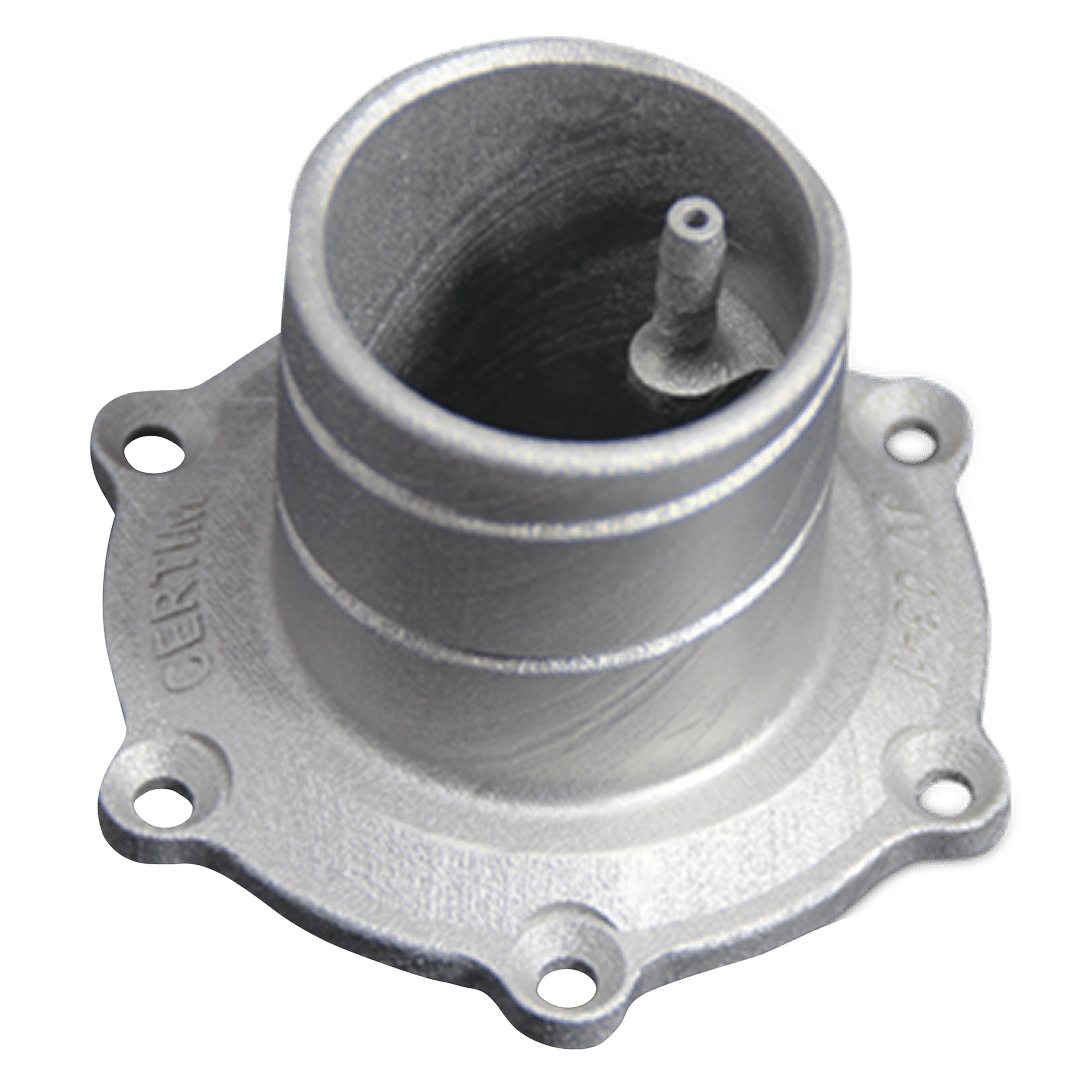

Metalmite Corporation can now print parts in a matter of hours made out of 17-4 Stainless, Tool Steel, Copper, Carbon Fiber, Nylon, or Kevlar, and more.

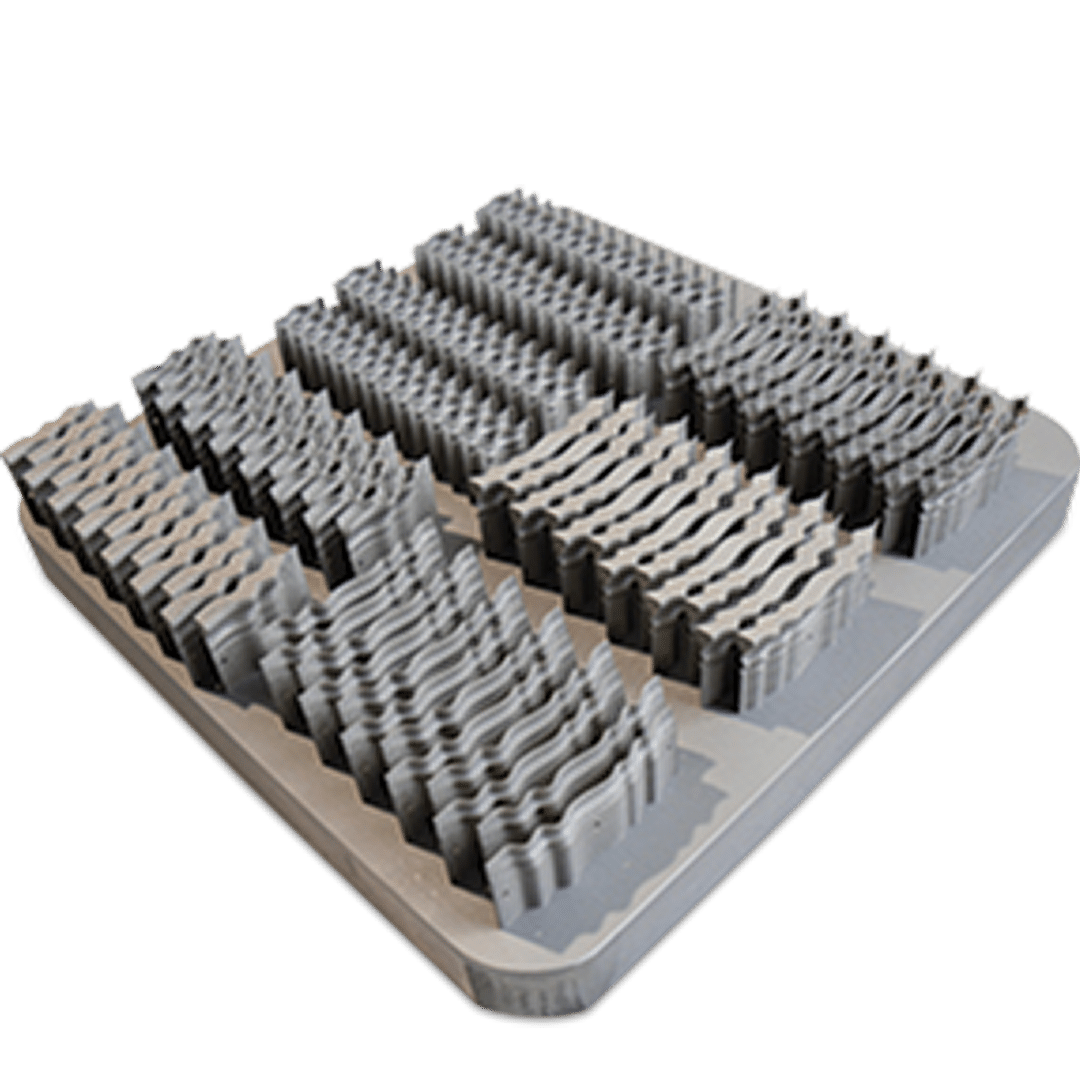

Metalmite now has a complete Print Farm with (3) Markforged MetalX printers and multiple FDM (fused deposition material) printers. The Markforged Metal X is a new kind of metal printer. By printing metal powder bound in a plastic matrix, Markforged has become the first company to eliminate the safety risks associated with traditional metal 3D printers. That means no loose powder, no lasers, and none of the traditional safety precautions. It’s safe to use in a shop environment with minimal facility upgrades.

In practice, the Metal X is essentially a very advanced FFF 3D printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap. More here.

The Mark Two is the best-in-class professional carbon fiber 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. More here.

SIGN UP FOR UPDATES!

Get news from Metalmite Corp. in your inbox.